CAS:9001-00-7

Storage:Store at RT,keep seal and dry

Product introduction

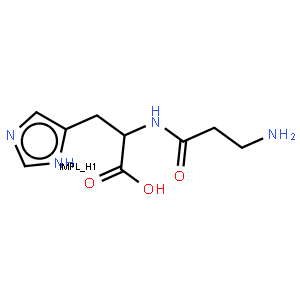

Bromelain is a group of sulfhydryl hydrolytic proteases extracted and refined from bromelipe-pineapple by bioengineering technology. The main component of bromelain is a protease containing sulfhydryl, but also contains peroxidase, acid phosphatase, several protein inhibitors and organic active calcium, its active center is sulfhydryl (-SH), can carry out various protein hydrolysis, biochemical reactions. Product features: bromelain comes from natural plants, with safety, non-toxic, wide range of action and other characteristics. Using advanced bioengineering technology: made by microfiltration, ultrafiltration, membrane separation and vacuum freeze-drying, the product quality has reached food grade and pharmaceutical grade standards, and passed the national export food production enterprise health standard certification.

Scope of application

It can be widely used in food, medicine and biological industries. Applications: 1. Bromelain is a natural, non-toxic and side-effect free protein. As a kind of sulfhydryl hydrolytic protease, it can hydrolyze proteins, hydrolyze peptide chains of protein molecules into polypeptides or amino acids, and form protein hydrolysates with unique flavor; 2. Bromelain has been proven to be a safe and effective therapeutic drug in the field of medicine, it can prevent platelet agglutination, fibrinolysis, anti-inflammatory effects, anti-tumor effects, cytokine and immunomodulatory effects, skin debridement, promote the absorption of other drugs, mucolytic effects, aid digestive effects, promote wound healing, improve the cardiovascular and circulatory system. Bromelain is well absorbed orally, and data suggest that it is more effective at higher doses.

Usage method

The optimal reaction temperature is 30-45 ℃, the PH value is 6-6.8, the addition amount is 0.2-1.0%, the most suitable temperature and pH value vary with the type and concentration of the substrate, and should be appropriately increased or decreased according to different substrates, and the reaction time is shortened or extended correspondingly in 3-8h. The optimal amount of enzymes must be determined according to the specific production situation.

Unit definition

Ultraviolet spectrophotometry: under the measurement conditions (37±0.2℃, pH 7.0),the absorbance of the TCA soluble substance released from hydrolyzed casein per minute at 275nm wavelength is equivalent to that of 1 microgram tyrosine, and the required enzyme amount is a unit of activity, expressed by u/g

Isoelectric point

9.55

Optimum pH

6.0—6.8

Optimum temperature

30—45℃

Note:Product information may be optimized and upgraded. Please refer to the actual label information for accuracy.

English

English

中文

中文